Factory For Corroded Brake Lines - Brake Bundy Tube – Jinxing

Factory For Corroded Brake Lines - Brake Bundy Tube – Jinxing Detail:

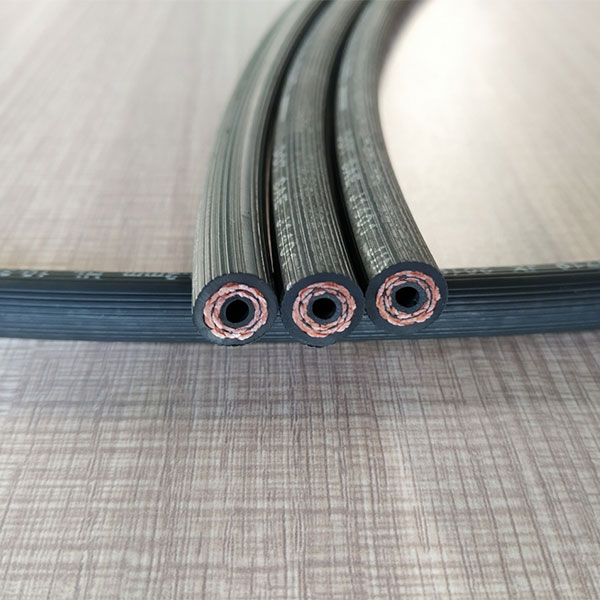

| PRODUCT | Brake Bundy Tube | PACKAGE | 200/250/300/500M/ROLL | |

| Type | Zinc coated/PVF coated | CERTIFICATE | IATF 16949:2016 | |

| MATERIAL | Stainless steel | Color | Olive green/colorful Zinc/Black | |

| PAYMENT TERM | T/T L/C | ORIGIN | HEBEI,CHINA | |

| SIZE | 4.76MM/6MM…….. | |||

1.Brake tube Material: steel

2.Tube color: Olive green/colorful Zinc/Black

3. Package: 200/250/300/500M/ROLL

4. Certification: IATF 16949:2016 CQC

5. Standard: GB16897-2010

6. Production Capacity:30000 Meters per day

7. payment terms: T/T L/C

8. Loading Port: Xingang port,Tianjin/ Qingdao/Ningbo/Shanghai

9. HOSE SIZE: 4.76MM/6MM……..

10. COVER LAYER TYPE: Zinc coated/PVF coated

The double layer welded pipe has good leakage resistance, high blasting performance, excellent reprocessing, outstanding anti-fatigue performance, high internal cleanliness, accurate geometry and so on. performance parameter: tensile strength Rm≥ 290Mpa Yield strength: Rel≥180Mpa Percentage elongation after fracture: A ≥ 25% The cleanliness of inner wall: Residue≤ 0.16g/㎡.

Common sense for selection and maintenance:

Please kindly note the following points when selecting the brake hoses:

1 Please select the brake hoses produced by the regular manufacturer and the hoses with the CCC mark, name of manufacturer and the production date.

2 Please choose the matching brake hose assembly according to the different models of Automobiles. Take care of the symbol on the hose body. If the tube letters “HR” represents the standard amount of expansion hydraulic hose; “HL” indicates a low amount of expansion hydraulic hose; “A” indicates that the hose used for pneumatic braking system; “V” means hose for vacuum brake system.

3 Please do not use the hoses which surface is with cracking, corrosion, bubbles and some other unqualified hoses.

4 Brake hose is the key important part to ensure the safety of vehicles traveling. So, it should be paid more special attention to the usual maintenance and regular checks to keep the hose surface cleaning and avoid corroding.

5 Please avoid the pull force.

6 Please kindly check the fittings of the brake hoses whether loose or not.

7 Long-term use of the brake hose, if there is aging, closed not tight or scratched, it should be promptly replaced.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Factory For Corroded Brake Lines - Brake Bundy Tube – Jinxing , The product will supply to all over the world, such as: Ghana, azerbaijan, Bangkok, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!