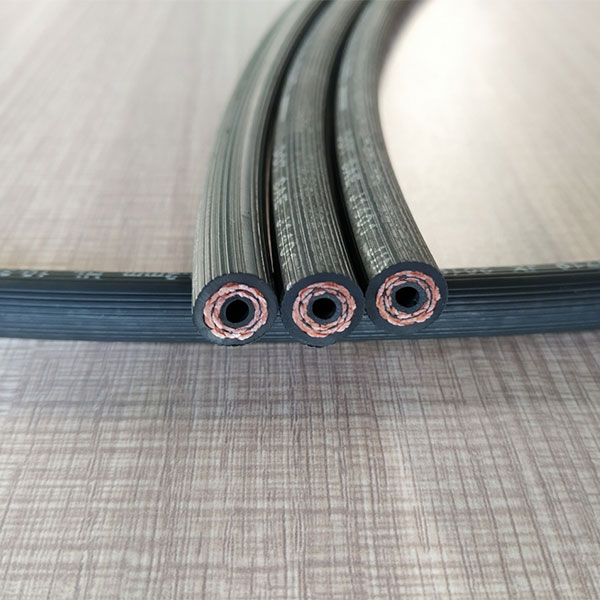

Hydraulic brake hose assembly

SAE J1401 DOT Hydraulic Brake Hose Assembly with competitive prices

Brake hose assembly is the very important part of vehicles brake system.

There are advanced production equipment and testing equipment in our company to ensure the quality of the products.

The brake hoses manufactured by us has the features of bursting strength, low volumetric expansion, excellent weather resistance and so on. The products are strictly in compliance with GB16897-2010, SAE J1401.

Material: EPDM, polyester thread

Feature: Low moisture permeation, extended service life, minimal volume expansion, excellent heat and ozone resistance.

Hydraulic brake hose: Cars, motorcycles, light trucks and other vehicles for hydraulic brake system.

The tests applied to our brake hose assemblies are:

100% PRESSURE PROOF TEST

ID CONSTRICTION TEST WITH BENT THE FITTING

EXPANSION TEST

BURST TEST

WHIP TEST

TENSILE TEST

WATER ABSORPTION TEST

LOW TEMPERATURE TEST

BRAKE FLUID COMPATIBILITY TEST

OZONE TEST

IMPULSE TEST

DYNAMIC OZONE TESTS

| No. | Test Items | Standard Specification | Test Result | ||

| 1 | 100%Pressure Test | 28MPa, Hold 120 Sec. | OK | ||

| 2 | Internal Channel Fluent Volume | ≥ Ф2.03mm | OK | ||

| 3 | VolumetricExpansion | 6.9 MPa | ≤1.08 mL/m | 0.45 | OK |

| 0.43 | |||||

| 0.44 | |||||

| 0.43 | |||||

| 10.3 MPa | ≤1.38 mL/m | 0.61 | OK | ||

| 0.58 | |||||

| 0.59 | |||||

| 0.57 | |||||

| Burst Test | 28MPa, Hold 120 Sec. | No Break | No Break | OK | |

| 4 | |||||

| Minimum Burst Pressure | ≥49.0 MPa,No Burst | 60MPa,No Burst | OK | ||

| 5 | Whip Test | ≥35H ,No Break | No Break | OK | |

| 6 | Tensile Test | ≥1446N,Hose No Break, Joint No Pull-out | 1600N,No Break No Pull-out | OK | |

| 7 | Low Temperature Resistance | -40+1℃, 72hrs,No breakage, No cracks | No Cracks | OK | |

| 8 | Ozone Test | 50+5ppm , 40℃+2℃, 72hrs,No breakage, No cracks | No Cracks | OK | |

| 9 | Salt Spray Test | 24H,No Base Metal Corrosion | No Base Metal Corrosion | OK | |