Short Lead Time for Internal Throttle And Clutch Kit - Brake Hose Assembly (standard by SAE J1401) – Jinxing

Short Lead Time for Internal Throttle And Clutch Kit - Brake Hose Assembly (standard by SAE J1401) – Jinxing Detail:

Brake hose assembly is the very important part of vehicles’ brake system. There are advanced production equipment and testing equipment in our company to ensure the quality of the products. The brake hoses manufactured by us has the features of bursting strength, low volumetric expansion, excellent weather resistance and so on. The products are strictly in compliance with GB16897-2010, SAE J1401. In addition, we have been applied for patents for many products.

Structure

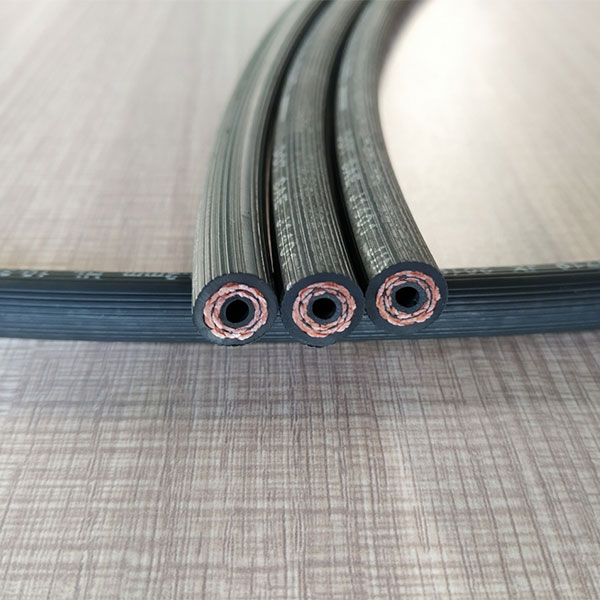

The hydraulic brake hose assembly is composed of a brake hose and a brake hose joint. There is a permanent connection between the brake hose and the brake hose joint, and the connection is realized by crumpling or cold extrusion of the joint part relative to the hose.

Performance requirements

The hydraulic brake hose assembly or the corresponding parts, under the above-mentioned test conditions, should be able to meet the performance requirements specified in this article when tested according to the following methods.

Inner hole throughput after necking

High flexibility and extremely small bending radius, light weight model extended to DN 76

Hose appearance: cloth texture surface (glossy surface is optional for inner diameter of 25.4mm or less)

Hose logo: printing or lettering

Hose color: black, red, blue, yellow, green, gray, etc.

main application

The installation space is small, medium and low pressure pipe, oil return pipe (suction pipe DN ≤ 31)

Mineral oil, rape oil and rapeseed oil, glycol and polyethylene glycol base oil, synthetic ester base oil, emulsified oil, water

Hose identification: HYDRAULIC HOSE EN857 1SC 1″(DN25) W.P 88BAR 1280PSI

Continuous working temperature range: -40°F / +212°F; -40°C / +100°C

Maximum working temperature: 250°F 121°C

Connector: SHF- withholding type

Inner rubber layer: oil-resistant synthetic rubber

Reinforcement layer: 1 layer of high tensile steel wire braid

Outer layer: weather-resistant synthetic rubber

Application standards: EN 857 1SC and IS 11237-1 1SC

Steel wire braided hose, high pressure hose, high pressure hose, hydraulic hose, hydraulic hose, armored hose, high temperature and high pressure oil hose for steel mill opening machine

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Short Lead Time for Internal Throttle And Clutch Kit - Brake Hose Assembly (standard by SAE J1401) – Jinxing , The product will supply to all over the world, such as: Philippines, America, St. Petersburg, We follow up the career and aspiration of our elder generation, and we are eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.